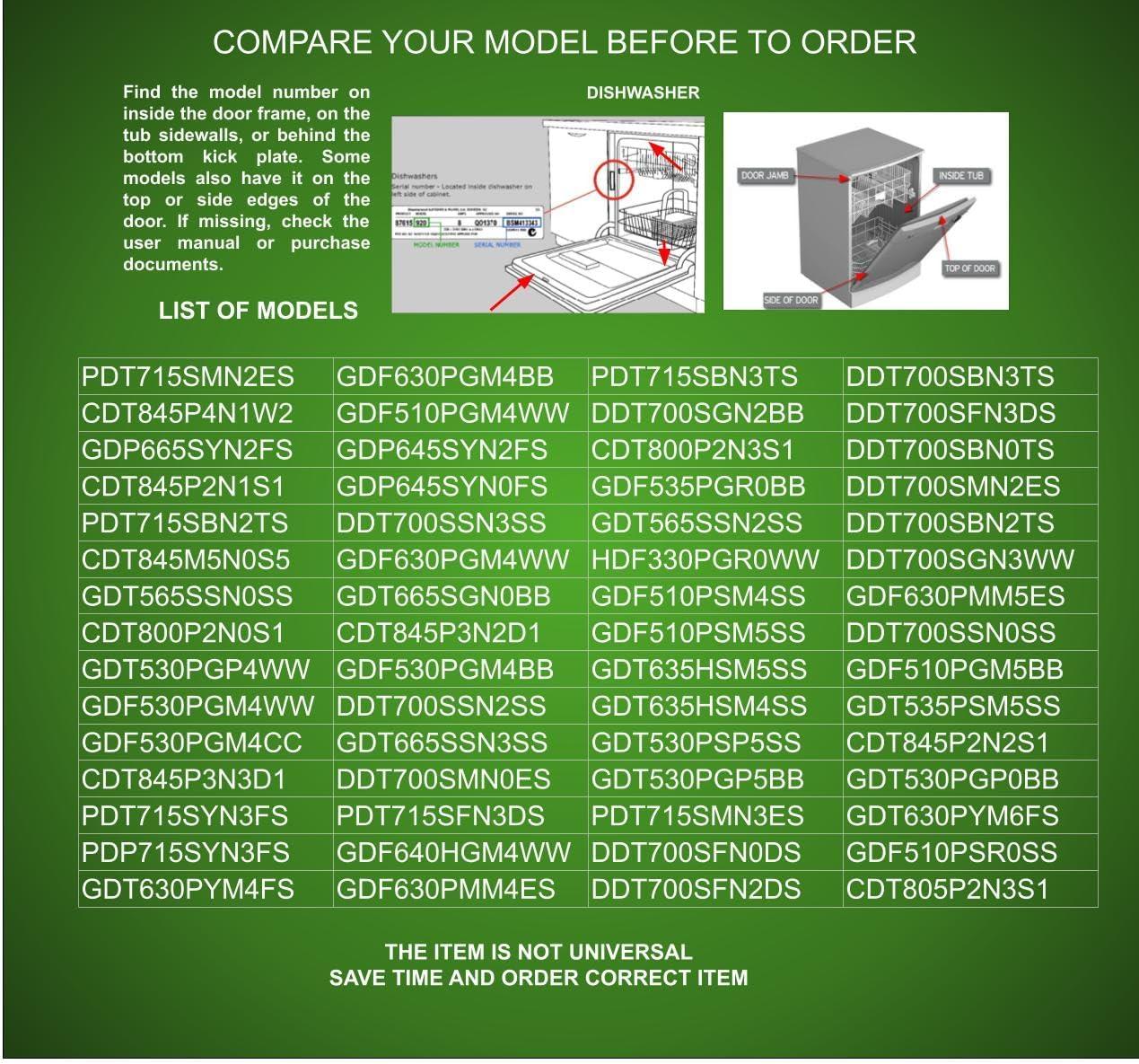

Johnson Electric E3320 EDRE3320X1 for your dishwasher repair

Under your hand the casing feels matte and lightly textured, its modest heft registering as reassuringly solid rather than flimsy. Turn it and the pump’s squat footprint and balanced weight become obvious—ports and mounting points line up neatly while molded ribs catch the kitchen light. Out of the box the Johnson Electric E3320 EDRE3320X1 had no sharp edges,and a small shake produces a soft internal rattle that settles as you position it. It sits in your workspace as a compact, tangible object: unobtrusive but unmistakably present.

When you peer under the dishwasher: the pump as it sits in everyday view and use

when you peer under the dishwasher the pump sits low in the cavity, tucked just behind the toe-kick and framed by hoses and wiring rather than standing alone. Its plastic housing presents as a compact, dark lump against the metal pan; over time you’ll often see telltale streaks, a light film of residue, and occasional mineral deposits where water has splashed or dripped. The electrical connector and a short length of cabling are clipped nearby, and the inlet and outlet hoses attach with simple clamps — nothing dramatic, just a clustered, functional arrangement. From this angle you can also pick out the mounting points and the way the pump nestles against the drain housing; parts are mostly recessed, so you tend to notice fingerprints or smudges from reaching in more than you notice bolts themselves.

In everyday use the pump announces itself by sound and motion rather than by sight: a brief, steady hum during drain cycles and a faint vibration that you can sometimes feel through the cabinetry. When you lift the lower panel during or after a cycle you may observe a fast rush of water through the hose or a small, sporadic drip where a clamp sits; occasionally small bits of food or film collect at the inlet and are visible without dismantling anything. Habitual interactions with the area are mostly visual checks and light tidying — wiping away grime, clearing obvious debris, straightening a hose — rather than prolonged work. A few things you’ll commonly notice at a glance:

- Pump body — compact, dark, often with surface deposits

- Electrical plug — clipped close and easy to spot

- Hose connections — short runs with visible clamps

- Mounting points — recessed and tucked behind the drain pan

These are the visual cues and small habits that define how the pump sits in everyday view and use.

When you pick it up: the casing,weight,and the small fittings your fingers register

When you lift it from the bench you notice the casing first: a matte-finished housing that gives a cool,slightly grainy feel beneath your palm. The weight sits more toward the motor end,so your hand naturally shifts as you cradle it — not light like a purely plastic part,but not so heavy that a single handed maneuver feels awkward. Seams and molded edges are visible where halves meet; they aren’t sharp, but you can trace them with a fingertip. Surface details — a shallow rib here, a stamped recess there — register as small tactile landmarks that help orient the piece when you’re fishing it into position or holding it up to compare to the part on the machine.

Your fingers pick out the small fittings next. There are tab-like snap points and stout screw bosses that give a firm, hollow click when pressed, and a short electrical connector tucked in a corner that resists for a moment before releasing from your grip. Rubber seals and a flexible grommet present a different texture, soft against the pads of your fingers and slightly tacky if they’ve been in service. Tiny nooks where water and residue tend to collect are easy to notice by touch — you’ll find yourself wiping them in passing, more as part of handling than as intentional maintenance. Tabs, screw bosses, and the connector all read clearly to touch, making placement and alignment feel incremental rather than guesswork.

Where you set it and how you maneuver the mounts during the install

You usually set the replacement down where you can reach it comfortably — on a small padded surface just outside the dishwasher opening or perched on the lip of the cabinet if you’re working from below. In that position the pump’s body is easy to see and the connection points face the area where the mounts live, so you can judge how the tabs and rubber grommets line up without wrestling in the dark. Common mount details that become obvious as you position the unit include:

- Alignment tabs that need to sit in little slots

- screw bosses that may require a slight rotate to engage

- Rubber grommets or cushions that compress and seat as the unit settles

These features are more helpful as visual cues than as measurements; you tend to rely on sight and a little fingertip pressure to confirm the pump is sitting where it will later fasten.

When you maneuver the mounts during the install you mostly work with small, responsive motions rather than forceful pushes. A slight tilt or a gentle twist often lines up a tab into its slot; the rubber mounts can feel springy at first and then give as the pump settles into place. Wiring and hoses usually dictate the final orientation, so you nudge the pump around the harness and then check that each mount has engaged — sometimes a subtle back-and-forth settles a stubborn clip. The following simple table summarizes how different mount types typically behave as you handle them:

| Mount type | Typical maneuver |

|---|---|

| Rigid tab | Requires precise lining up,then a small push to seat |

| Rubber grommet | Compresses slightly as the pump settles; forgiving of small misalignments |

| Screw boss | Frequently enough needs a tiny rotation to match threads or holes |

Little,repeated adjustments are common; you often pause,look from a different angle,and make one more nudge until the mounts sit as was to be expected.

What you notice during a cycle — the drainage motion, sounds, and timing you observe

During a run you’ll notice the drain action as a distinct phase: water stops sloshing and the machine’s rhythm shifts into a more focused, directional flow. Often this happens once after the main wash and again after the final rinse; each drain sequence tends to be short — roughly a few dozen seconds to around a minute — though the exact moments vary with the program you picked. Visually you may see the remaining water level drop in stages rather than all at once, and sometimes a brief pause or restart occurs as the pump clears an air pocket or the trap. Small adjustments you make — nudging a rack, shifting tall items — can change how quickly water evacuates from a particular corner of the tub, so the motion can feel a bit situational in everyday use.

The sounds are a helpful cue. You’ll hear a steady, even hum as the pump runs, a slightly higher-pitched whir when it’s pushing through a tighter outlet, and intermittent gurgling as air and water pass through bends. Occasionally there’s a faint click or clack as valves open or as water cascades past the drain path; if something gets momentarily caught you might notice a brief rattle that fades once the flow steadies.

- Hum/whir: sustained during active pumping

- Gurgle: when air mixes with draining water

- Click/rattle: transient, tied to valve or debris interactions

All of this tends to settle quickly — the tone frequently enough shifts to a lower, shorter final sound as the pump finishes and the cycle resumes — and it becomes part of the routine background noises you expect from a normal dishwasher cycle.

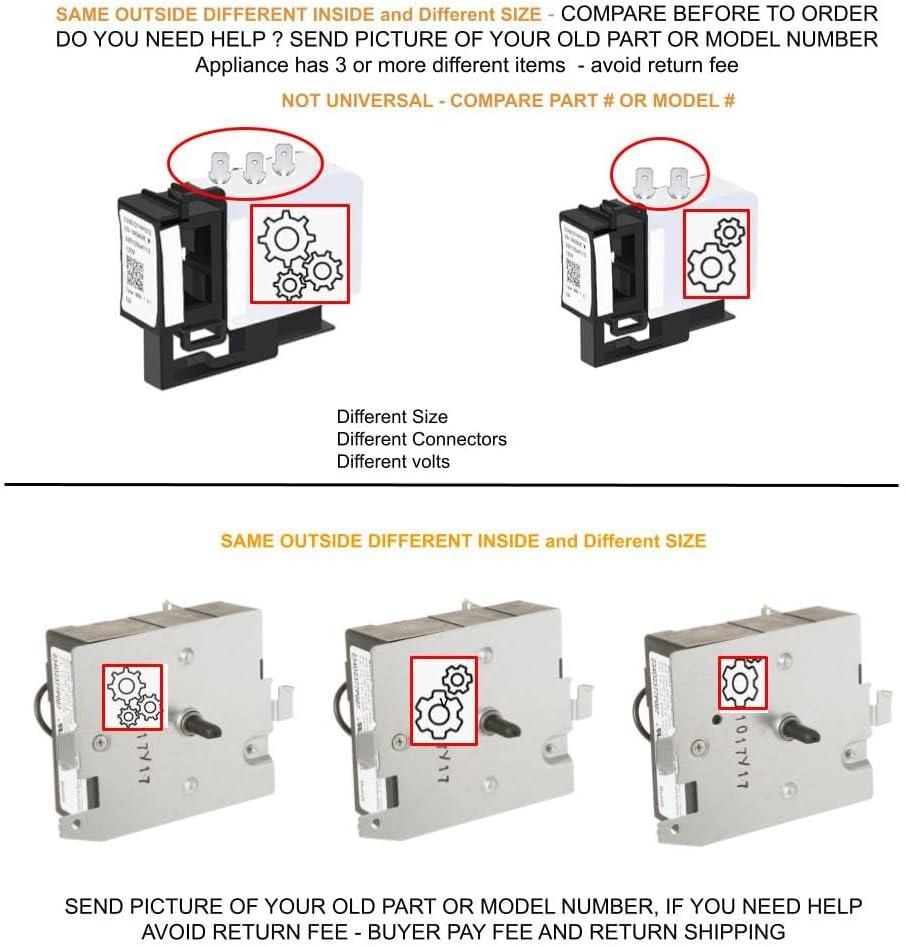

How closely this compatible E3320 matches your old Johnson Electric part and where you may encounter limits in service

the replacement generally mirrors the original part’s physical layout during routine handling and installation: mounting points and the plug-style harness line up in most installations, the impeller sits in the same orientation, and the pump cycles produce similar flow and clearing behaviour under normal dishwasher loads. The casing and molded features can feel a bit different to the touch, and the visual fit of clips or tab tolerances sometimes requires a small nudge to seat fully; these are practical, hands-on differences rather than wholesale design changes. In everyday use the motor speed and drain timing tend to behave like the original, with only minor audible character changes on some runs.

Limits in service appear where system tolerances or preexisting wear are already marginal. Small differences in sealing lip profile or outlet alignment can lead to occasional weeping with older gaskets, and a few installations with very tight hose routing or unusual brackets may need slight repositioning to avoid chafing. Electrical compatibility is broadly maintained,though thermal protection designs and long-term durability can vary enough that extended heavy-duty cycles or repeated hard starts reveal divergence over time. Examples of commonly observed constraints include:

- Alignment tolerance: matches mounting pattern but may sit a hair differently in cramped spaces;

- Seal interface: sealing surfaces align, yet older gaskets sometimes require attention;

- Connector fit: plug mates without force but routing can change under strain;

- Service life signals: audible tone and wear patterns can differ subtly after many months of heavy use.

| Observed match | Where limits show |

|---|---|

| Mounting footprint aligns | Tight cavities or legacy brackets |

| Plug-in electrical connection fits | Damaged or stretched harnesses |

| Similar drain performance on routine cycles | Frequent heavy-soil loads or hard-start conditions |

See the complete listing and specifications for configuration details here.

The maintenance cues you notice over weeks of use and the routine checks you end up doing

Over the first few weeks you tend to tune into a small set of signals that the drain area is giving you. At first it’s mostly sound: a steady, mechanical hum when the cycle reaches the drain step, and sometimes a quieter rattling if a fork or small piece of debris shifts. After several loads you might notice the drain phase starting a little later than it used to, or a soft gurgle before the pump kicks in; those timing shifts are subtle but noticeable when you’re used to the machine’s rhythm. You’ll also catch tiny visual or tactile clues — a faint wet patch under the unit after an extended sanitize cycle, a slight warmth to the kickplate area, or a short-lived smell after heavily soiled loads — that make you check the base or the filter area more frequently enough than you did at first.

Those cues shape a handful of quick, habitual checks you end up doing without thinking. You listen at the start of a drain cycle and glance under the door afterward for dampness, lift the filter housing to eyeball any visible gunk, and give the hose routing a look when something sounds off. Common items you notice and keep an eye on include small drips, louder-than-usual vibration, and residue build-up near the pump outlet; to keep those observations clear you tend to revisit the same spots.

- Sound check: a brief listen during drain cycles for new rattles or whines.

- Visual check: quick look under the door and around hose connections after a long wash.

- Touch check: feeling the kickplate or access panel for unusual warmth or dampness.

| Cue | What you usually notice next |

|---|---|

| Delay in draining | A faint gurgle or longer hum at the drain step |

| Intermittent drip | A small wet spot near a hose or the cabinet floor |

How It Settles Into Regular Use

Over several weeks the EQUIP. DR US Johnson Electric E3320 EDRE3320X1 compatible with GE Dishwasher Drain Pump fits old part number Johnson Electric E3320 has slipped into the quiet background of the kitchen, folded into the machine’s usual rhythms. It rarely draws attention; the surrounding cabinet and the dishwasher door carry the faint smudges and small scuffs that come with everyday loading, while the pump itself is mostly hidden and shows only the mild, gradual wear of regular use. In daily routines it becomes something to expect — a low-level presence in household patterns, noticed mostly when a cycle pauses or when hands reach for a dish.Over time it settles into routine.

As an Amazon Associate I earn from qualifying purchases. Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates. All images belong to Amazon