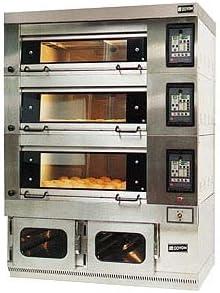

Doyon 2T-4 Four Deck Artisan Stone Oven: your prep station?

you feel the mass before anything else — a deliberate heft that registers under your palms the moment you touch a deck. You spend a morning with the doyon Baking Equipment 2T-4 Four Deck Artisan Stone Two Pan Electric Deck Oven — the 2T-4 — and you notice the cool stainless skin, the tight seams and rivets, and how those surfaces catch light differently where they’ve been handled.When you open a door the hinge gives a firm, slightly damped clunk and the stone deck edge feels textured and blunt under your fingertips; a low electrical hum settles into the background as the oven powers up. From across the room the stacked decks create a compact, industrial vertical line — heavy, balanced, and immediately present in the space without any theatrics.

What you notice first when you wheel the oven into your prep area

The first thing you register is the sensation of momentum — it moves, but it moves with presence. As you push it across the floor the weight translates into steady resistance under the casters; steering takes small, intentional nudges rather than rapid swivels.The front face and handles come into view before the decks do, so your hands naturally check the latches and give the door a light pull; there’s also a faint new‑metal scent and a few packing stickers that catch the light and your attention. Sounds are immediate too: a low rumble from the wheels, the scrape of the floor when you correct course, and the brief clank if your line of travel brushes a prep table, all of which shape how you place it in the room.

Once it settles in place you notice a few practical things at once:

- Wheels and footing — how the casters sit on the floor and whether they lock or roll freely,which affects small repositioning.

- Front‑facing controls and handles — where you reach for doors or knobs without stepping around the unit.

- Surfaces and clearances — how the stainless fronts show fingerprints, how much space remains behind for cables or ventilation.

these impressions tend to shape the quick adjustments you make — shimmying the unit a fraction, sweeping away crumbs that collected during the move, or angling it slightly so the doors open without hitting nearby equipment. Routine upkeep registers too in that moment: you notice corners where dust likes to gather and the kinds of surfaces you’ll be wiping down most often.

How the exterior, decks and materials feel under your hand as you inspect it

When you run a hand over the exterior, the first impression is the contrast between cool, brushed metal panels and the warmer, denser-feeling door and handle. The stainless surfaces have a fine grain you can feel with your fingertips; seams and welds are visible and you can trace a slight ridge where panels meet. Doors move with a measured resistance — the hinge and latch give a firm, purposeful touch rather than a loose or spongy one — and the handle itself feels significant in the palm, with a rounded profile that doesn’t bite into your grip. Control knobs rotate with a palpable detent; the dial faces and label plates sit flush enough to avoid catching, but you can still feel their edges if you follow them with your finger. panels have only a little flex when you press, and vents and access points present crisp edges that you notice more with a light, exploratory sweep than with a normal pass-by inspection.

Opening a deck and inspecting the oven surface shifts the tactile story: the stone decks have a textured, slightly grainy surface that tends to hold small crumbs and flour particles, so your fingertips pick up a dry, dusty feel unless they’ve been brushed recently. The seams where stone meets metal are tangible under finger—there’s a narrow lip or joint you trace as you move from hearth to frame. If the unit has been used recently, heat transfer is immediate; the stone gives a soft, radiant warmth and the metal deck frame feels hotter to the touch. As part of routine handling you may find these recurring touchpoints useful to note:

- Exterior panels: cool, brushed texture with subtle weld ridges

- Door and handles: heavy, rounded grip and firm hinge resistance

- Deck surfaces: porous, grainy stone with discernible seams

| surface | Tactile note |

|---|---|

| Brushed stainless | Fine grain, cool to touch, slight panel give |

| Door handle & hinge | Solid, rounded, definite resistance when operated |

| Stone deck | Textured, dry/gritty feel, warms quickly after use |

Where the controls, doors and pans sit when you reach to operate them

When you stand in front of the oven, the controls present themselves on a single band above the decks so your hand meets them after a short forward reach. Knobs, switches and any display are grouped across that band, so you tend to move along it with your fingers rather than re-positioning your whole body. In normal use you reach past a slightly protruding door lip and often pause with one hand on the handle while the other adjusts a dial or the timer; that small, everyday choreography — a quick reach, a tap, a return to the door — is what most interactions feel like. Routine tidying (brushing away stray flour or a quick wipe of a finger) happens in the same motion, rather than as a separate step.

The doors and the pans inside sit low enough that you reach in with a level forearm, and the pan edges are easy to feel before you lift. You’ll usually use a short lateral motion to slide a pan forward from the stone deck, and the oven’s layout makes those touchpoints predictable.Typical things you touch when operating the unit include:

- Control knobs — along the top front band

- Door handles — centered on each deck opening

- Pan rims — which you encounter as you withdraw or insert trays

| Component | Where it sits when you reach |

|---|---|

| Control bank | Across the front, above the doors — reachable with a short forward lean |

| Door handle | At the door edge — encountered first as you open or steady the door |

| Pans | On the stone deck, slightly recessed so you slide them forward to grasp the rim |

How much floor and vertical space it asks of your kitchen and where you might place it

The unit occupies a clear, unavoidable presence on the floor: it’s floor footprint and height translate into a tall, heavy appliance that tends to stay put once installed. in routine use it requires unobstructed front access for loading and unloading, and some sideways breathing room to reach control panels or pull the decks open; service access behind the unit is also commonly needed for electrical hookups and occasional maintenance. As of its mass and bulk,moving it around feels like an event rather than a quick rearrangement,and floors under it are experienced as load-bearing areas rather than casual storage spots. During cleaning cycles the area immediately in front and at least some side clearance are the parts most interacted with, while the top and back generally remain out of regular reach.

| Characteristic | Typical measurement (contextual) |

|---|---|

| Approximate installed width | ~56 in — fits in a single-wall bay |

| Approximate installed depth | ~46 in — requires forward work clearance |

| Approximate installed height | ~79 in — reaches above most prep counters |

| Installed weight | ~2400 lbs — usually treated as fixed equipment |

Common placement patterns in professional kitchens tend to include:

- built flush against a non-combustible back wall with operator space in front;

- lined up with other production ovens in a continuous bake line;

- positioned where electrical service and ventilation reaches are readily available.

For the complete technical listing and configuration details, see the full specifications here.

How it measures up to the rhythms of your daily service

Across a typical service day it becomes a fixed point in the kitchen’s choreography: an initial warm-up that sets the pace, a steady interval of timed loads and brief door exchanges, than quieter periods for light tidying. The oven’s thermal mass and deck surface show up in the way batches are staggered—there’s a recognizable rythm where one deck is coming down to finish while another is still rising to peak temperature. Staff often build small habits around that rhythm, pausing to rotate pans or wait a minute longer for carryover to finish, and the controls provide quick visual confirmation so those pauses don’t feel like guesswork. During rush periods the movement is brisk and repetitive; during slow periods operators take the chance to clear pans and wipe surfaces in between cycles, nothing elaborate, just routine touch-ups that keep the station functioning without disrupting flow.

Routine upkeep happens in the gaps rather than as a separate task: scraping crumbs,brushing the stone surface when cool, and wiping controls during lull times become part of service flow rather than an isolated chore. The oven’s presence also shapes layout decisions—staging space for incoming pans, a short clear area for unloading, and electrical hookups that remain in the mental map of staff shifts. small limits show up too; after a sustained run there can be a short recovery interval before the next heavy load is introduced, so sequence planning tends to include short rests. Morning prep often feels different from late service in how batches are sequenced and cleaned, and those patterns tend to settle in after a few shifts. View full specifications and configuration details

What you see at the end of a shift as it cools, you clean it and it sits idle

As the last trays come out and the element indicators wind down, you notice the oven change from active to dormant: the deck stone loses its faint warm glow, the door glass cools to a touch, and small wisps of steam fade from the seams. On the deck itself there are the usual telltales — a scatter of crumbs in the corners, a thin grease sheen near the loading edge, and darker spots where dough met stone — all visible without tools. You perform your routine tidy-up: a quick brush of the crumbs, a cloth over the door handle, and the occasional nudge to line up a rack; these motions are habitual, part of the end-of-shift rhythm rather than a checklist you recite. Residual heat is still perceptible near the back for a while and the control panel sits dark, its lights extinguished except for any small status LEDs that tend to blink on and off as systems cool.

After cleaning, the unit sits idle and becomes part of the quieter kitchen landscape. You might leave the door slightly ajar or close it fully depending on the night’s routine, and a faint dusting of flour or a single fingerprint on stainless will be the only visible reminders of the day. A short unnumbered list that frequently enough matches what you see at this stage:

- crumb lines along the deck seams

- a soft satin of polish on stainless panels

- one or two cooling-warm spots near vents

Below is a small snapshot table of typical surface observations as it cools and sits idle, shown for quick reference.

| Area | What you typically notice |

|---|---|

| Deck surface | Color variations where scrubbed; scattered crumbs at edges |

| Door and glass | Faint streaks from wiping; cooler to the touch after a short time |

| Control console | Mostly dark; occasional status LED blink as systems settle |

How It Settles into Regular use

Living with the 2T-4 four Deck Artisan Stone two Pan Electric Deck Oven over time, you notice it taking on a quiet role in the kitchen, present in the background of regular household rhythms rather than demanding attention. The surfaces collect the small smudges and soft abrasions that come from constant use, the space around it adapting as routines shift and work flows to and from its doors. In daily routines you mark the same small motions — sliding trays, a quick wipe, the familiar pause to check — habits that make it part of ordinary days. it settles into routine.

As an Amazon Associate I earn from qualifying purchases. Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates. All images belong to Amazon