Our Honest Take: DTF Printer A3’s Quality, Speed & Setup Cheers

When we first unboxed the DTF Printer A3 – a high-speed transfer machine boasting a white ink mixing system and a convenient roll feeder – we were eager to see how it would transform our DIY t-shirt printing projects. Known for its promise of vibrant colors and razor-sharp detail, this printer instantly caught our attention with its compact design and innovative features. Over the past few weeks, we’ve put it through its paces, navigating the setup, testing print quality, and exploring its speed and functionality. In this review, we’ll share our firsthand experience, highlighting what makes the DTF Printer A3 a compelling choice for hobbyists and small creators alike, along with some of the hiccups we encountered along the way. let’s dive in!

Overview of the DTF Printer A3 and Its Core Capabilities

Combining innovative technology with user-focused design, this A3 transfer machine stands out as a versatile tool for DIY t-shirt enthusiasts and small-scale businesses alike. The integrated white ink mixing system is a game-changer, ensuring smooth and consistent ink flow that prevents clogging-a common issue in many DTF printers.This feature guarantees vibrant, long-lasting prints with exceptionally sharp details, bringing even the most intricate designs to life. Thanks to the high-speed XP600 printhead, it offers a remarkable boost in printing efficiency, reportedly doubling the speed of conventional DTF printers without sacrificing quality. Plus, its space-saving design, featuring an integrated ink tank and a sleek footprint, helps maintain a tidy, professional workspace.

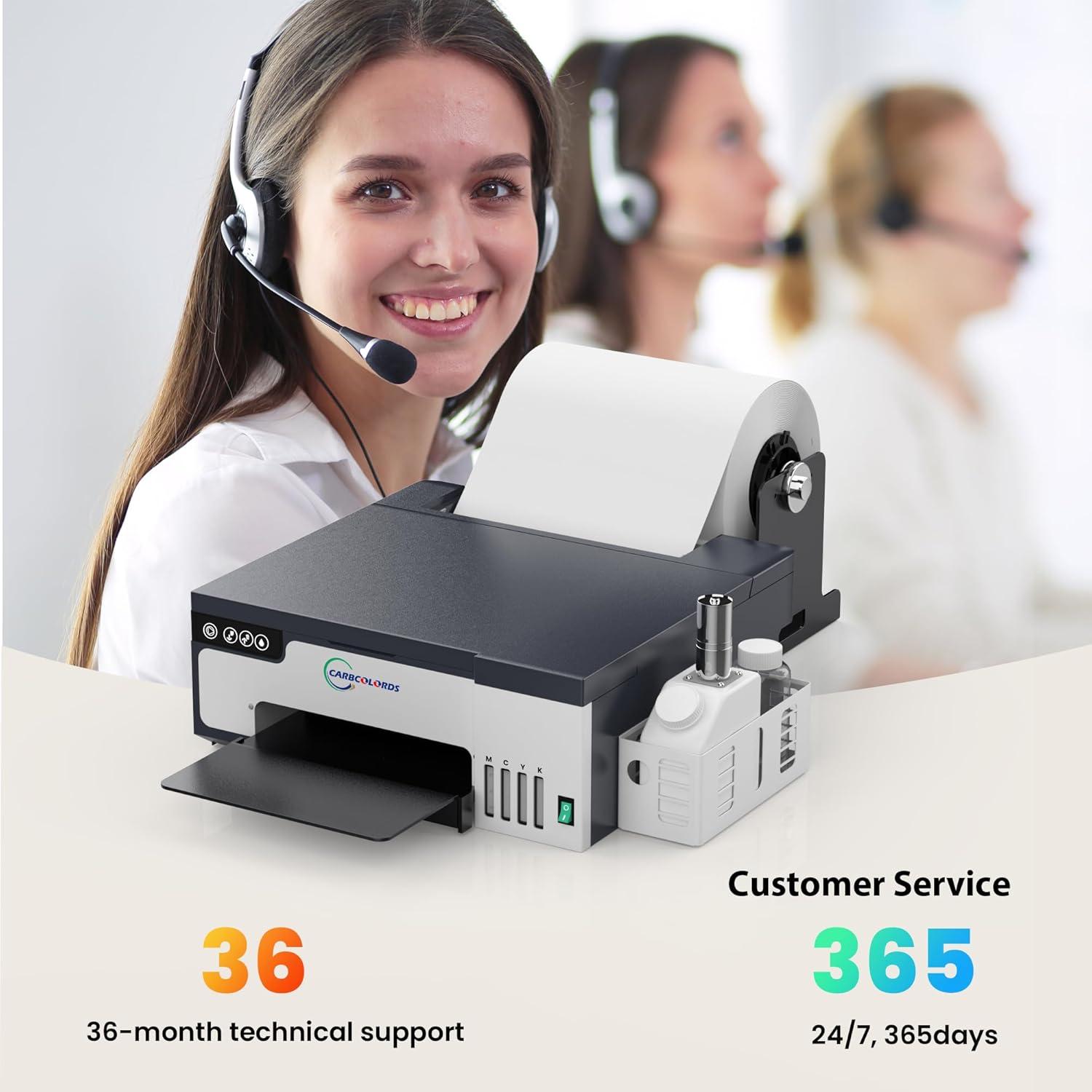

Setup experiences vary,but detailed manuals and accessible customer support make navigating any initial learning curve much easier. The machine’s roll feeder simplifies handling film rolls, streamlining the workflow significantly. Users praise its quiet operation during normal printing,though noise can increase briefly during printhead cleaning cycles. Here’s a swift glance at its core capabilities:

- Ink System: Innovative white ink stirring mechanism

- Print Speed: Up to 200% faster than standard models

- Print Quality: High resolution with crisp, vibrant colors

- Design: Compact and integrates ink tank for space efficiency

- Feed Mechanism: Convenient roll feeder for continuous printing

| Feature | Benefit |

|---|---|

| White Ink Mixing System | Prevents settling and clogging for flawless prints |

| XP600 Printhead | Delivers high-speed, detailed output |

| Roll Feeder | Supports seamless, continuous printing |

| Compact Size | Saves valuable workspace |

| Support & Setup | Extensive resources plus responsive customer service |

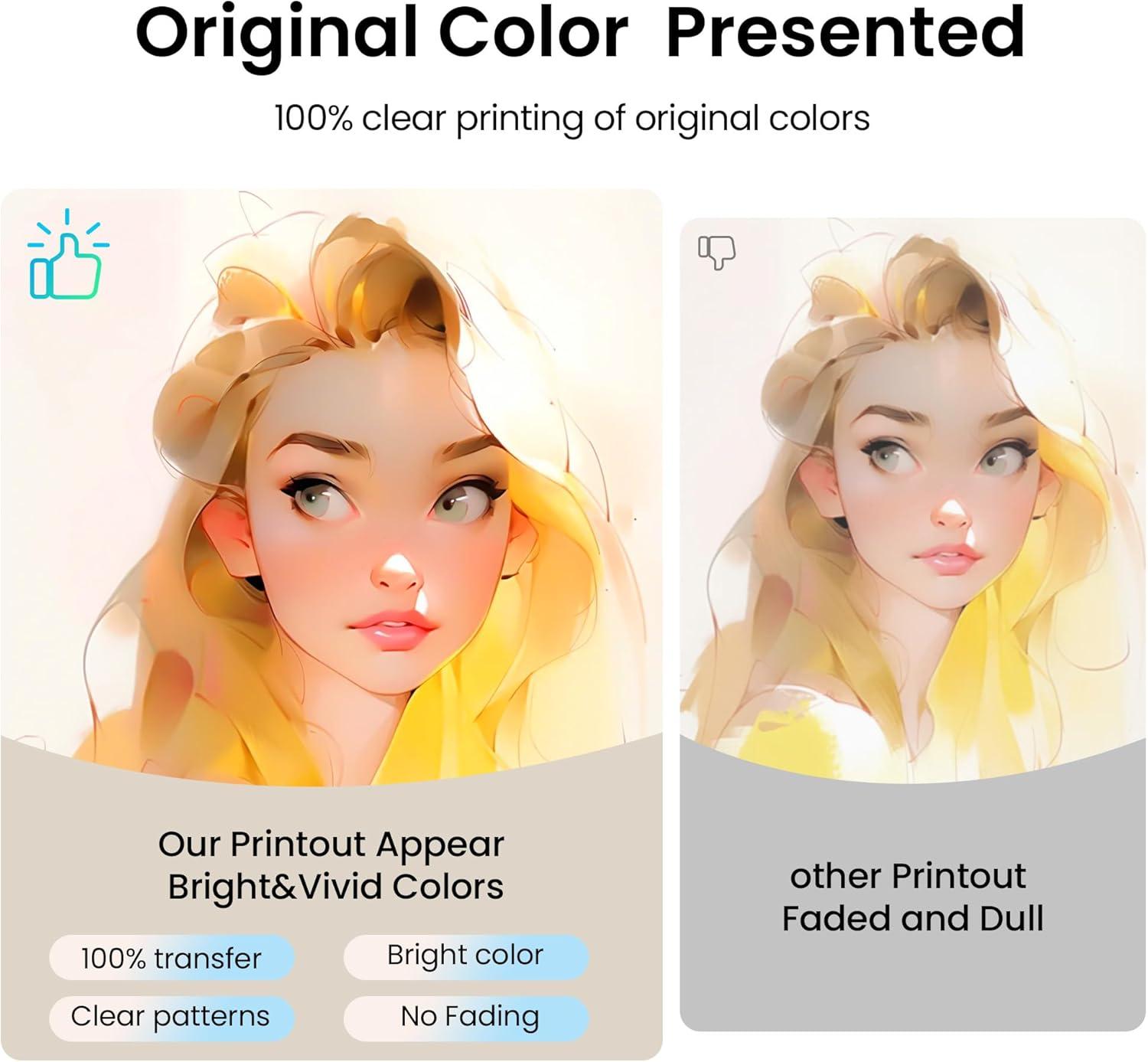

Exploring the White Ink Mixing System and its Impact on Print Quality

one of the standout features in this machine is its innovative white ink mixing system, designed to keep the ink flowing smoothly and consistently. This system prevents common problems like ink settling and clogging, which often plague DTF printers using white ink. Consequently, our prints come out vibrant and uniform, maintaining sharpness and density across the entire image. We noticed that the consistent agitation helps achieve a flawless opacity of white underbase layers, which is critical for colorful and lasting transfers onto darker apparel. This innovation truly elevates the quality of final outputs, turning even complex designs into crisp, vivid masterpieces.

Beyond quality, the mixing system also improves reliability, reducing downtime for maintenance and cleaning. Users have reported smoother operations without frequent interruptions caused by dried or uneven ink deposits. Coupled with the rapid printing speed facilitated by the high-performance printhead, it creates an efficient workflow ideal for small businesses or hobbyists aiming for professional-grade results. Below is a quick overview of how the white ink mixing system enhances the printing process:

- prevents ink settling and clogs for consistent output

- Maintains brightness and opacity of white ink base

- Reduces printer downtime through less frequent maintenance

- Supports rapid printing speed with high-quality results

| Feature | Benefit |

|---|---|

| Continuous Ink Stirring | Prevents pigments from settling |

| Consistent Ink Flow | Ensures even color distribution |

| Rapid Print Speed | Boosts production efficiency |

| Compact Ink Tank | Space-saving and easy refills |

the white ink mixing system significantly impacts our confidence in the print quality and durability of transfers. Although setup initially required some patience,once properly calibrated,this printer delivers outstanding results that justify the learning curve. We recommend it to anyone serious about producing durable, eye-catching designs with consistent white ink coverage and vivid colors. Ready to elevate your printing game? Check it out on Amazon.

Understanding the Roll Feeder Functionality for Seamless Printing

The roll feeder system integrated into this transfer machine significantly streamlines our printing workflow, especially for continuous production of DIY t-shirts. Unlike manual sheet feeding that can be prone to jams or misalignment, the roll feeder ensures smooth, consistent film feed throughout long print runs. This not only reduces the chances of errors but also saves us valuable time during setup and printing. The gentle tension control built into the feeder maintains perfect alignment,allowing each print to emerge flawless without interruptions or wasted material.

Its design is notably space-efficient, fitting neatly into our compact workspace without adding bulk. Key benefits we’ve experienced include:

- Improved print accuracy due to consistent film movement

- Reduced manual labor by automating film feeding

- Smoother operation that lowers noise levels and mechanical strain

- Enhanced reliability with fewer paper jams or misfeeds

| Feature | Benefit |

|---|---|

| Automatic Roll Feeding | uninterrupted print job workflow |

| Tension Control | maintains precision for clean edges |

| Compact Design | Optimizes workspace, ideal for small studios |

| Easy Loading | Quick replacement of film rolls |

this roll feeder functionality elevates the usability of the machine, making it an excellent choice for both hobbyists and small businesses looking to improve print consistency and efficiency without sacrificing quality.

Assessing Print Speed and Efficiency in Real-World Use

When put to the test under real printing conditions, this machine truly impresses with its rapid output, largely thanks to the advanced XP600 printhead that reportedly doubles the speed compared to standard DTF printers. We’ve found that the roll feeder system streamlines continuous printing, allowing us to work on multiple t-shirt designs without constant interruptions. Though some users noted a learning curve during setup, once operational, the workflow becomes smooth and efficient. the integrated white ink mixing system also plays a vital role, ensuring consistent ink flow which reduces downtime caused by clogs or ink settling, a common issue in many transfer printers.

efficiency extends beyond just speed. The space-saving design and ink tank integration minimize clutter and simplify maintenance, which helps us stay productive during demanding projects. However, noise levels do rise briefly during print head cleaning cycles, though this is a small trade-off for the overall quiet operation. Below is a quick overview comparing key performance aspects we experienced in day-to-day use:

| Feature | Performance Highlights |

|---|---|

| Print Speed | Up to 200% faster than conventional models; steady roll feeder operation |

| Ink consistency | White ink mixing system prevents clogging; smooth output |

| Noise level | Minimal, except brief spikes during cleaning cycles |

| Setup ease | Mixed experiences; excellent customer support available |

| Workspace Efficiency | Compact design with integrated ink tank conserves space |

For those exploring efficient, high-speed direct-to-film printing solutions that balance performance and workspace neatness, this model is worth serious consideration.

Evaluating Ease of Use and Setup for DIY T-Shirt Projects

Setting up this printer for our DIY T-shirt projects was a mixed experience, but overall manageable with the right resources.The package includes a detailed manual and helpful video tutorials that guide users through the initial assembly and installation processes. Thanks to the compact and space-saving design, it fits comfortably in most home workspaces without feeling intrusive. Installation of ink and paper loading was straightforward for us, especially with the mess-free ink bottles and clear instructions provided. However, some of our team members found configuring software and white ink settings a bit daunting at first, which is where the responsive and informed customer service truly shines – quick assistance made all the difference in navigating the learning curve.

Key highlights of the setup experience include:

- Step-by-step manual paired with YouTube video tutorials

- Space-efficient and sleek design enhances workstation setup

- Ink bottles designed for easy, mess-free refills

- Support team available around the clock to solve setup challenges

| Setup Aspect | User Feedback |

|---|---|

| Physical Assembly | Mostly easy with clear instructions |

| Software Installation | Some users required extra help |

| Ink Loading | Mess-free and convenient |

| Customer Support | Highly praised for responsiveness and expertise |

For those willing to invest a little time upfront, this printer offers a rewarding setup and user experience that translates into high-quality prints. If you’re ready to elevate your DIY t-shirt game with minimal hassle, check it out here and start printing vibrant, professional transfers in no time!

Comparing Direct to Film Printing Results with Other Methods

When we compare direct to film (DTF) printing to other popular methods like screen printing and direct-to-garment (DTG), the differences become quite clear.Our experience with the A3 DTF machine highlights vivid, bright colors and sharp details that frequently enough surpass screen printing’s initial vibrancy, especially on darker fabrics. Unlike DTG, this method doesn’t require pre-treatment of garments, saving time and reducing setup complexity once mastered. The innovative white ink mixing system ensures consistent opacity and no ink settling, which means printed designs maintain their integrity after multiple washes. While DTG can sometimes struggle with color saturation on certain materials, this DTF system bridges that gap elegantly with clean, long-lasting transfers.

Functionality-wise, the roll feeder and high-speed printhead significantly boost productivity compared to manual heat-press transfers or slower direct printing processes. Though there’s a learning curve to setup and calibration-common in most advanced printers-the printer’s ink flow stability and smooth operation stand out as major advantages.Noise levels remain moderate, only noticeable during head cleaning cycles, a minor inconvenience compared to some louder industrial printers. Below, we’ve summarized key comparisons to help you see where this DTF solution fits:

| Criteria | DTF Printing (A3 Machine) | Screen Printing | Direct To Garment (DTG) |

|---|---|---|---|

| Print Vibrancy | High, lasting vivid colors | Good, strong on bulk runs | Moderate, can fade faster |

| Setup Time | Moderate; initial learning curve | long; stencil preparation | Short; no stencils required |

| Material Compatibility | Works on many fabrics easily | Great for cotton and blends | Best on cotton |

| Production Speed | High speed with roll feeder | Fast in bulk volume | Slower per piece |

| Color Opacity | Excellent, due to white ink system | Excellent on fabric | Varies; less opaque on darks |

In short, for those of us seeking a reliable, flexible printing method that combines impressive print quality with efficient production, this DTF printer is a strong contender. It particularly shines for DIYers and small business owners looking for dramatic, durable results without the complexity of conventional methods. Want to see the difference yourself? Experience the quality firsthand and elevate your custom apparel game today.

our recommendations for Maximizing the Potential of the A3 DTF Printer

To truly get the most out of this printer, we recommend focusing first on mastering the setup process. While some users find it straightforward, others experience a learning curve that can feel challenging at first. Take advantage of the detailed manuals,video tutorials,and especially the responsive customer service-these resources are crucial when configuring the white ink mixing system and adjusting your print settings for optimal output. Setting up the roll feeder correctly and ensuring ink bottles are installed properly will prevent common issues such as jams or ink flow interruptions. We also advise keeping the USB software key safely attached via a multi-port hub to avoid misplacement, as the printer’s software depends on this for operation.

Maintaining smooth operation means regular upkeep is essential. Daily cleaning and proper handling of the XP600 printhead maximize the printer’s remarkable speed and print quality, giving vibrant, long-lasting results.Noise levels stay minimal during printing but can spike briefly during maintenance cycles, so consider placing your setup in a well-ventilated, quieter area if noise is a concern. Below, we share a quick maintenance schedule to help safeguard your investment and keep your production running efficiently:

| Task | Frequency | Tip |

|---|---|---|

| White Ink Mixing System Check | Daily | ensure smooth stirring to prevent clogging |

| Printhead Cleaning | After every 50 prints | Use recommended cleaning solution to maintain sharpness |

| Roll Feeder Alignment | Weekly | Adjust tension to avoid paper jams |

| Software & Driver Updates | As available | Keep firmware updated for best performance |

By embracing these practices, we have noticed a significant boost in print quality and machine reliability, making this printer an remarkable choice for both hobbyists and small business creators. Ready to elevate your t-shirt printing game? Get Yours Now

pros & Cons of the DTF Printer A3

After putting the DTF Printer A3 through its paces and listening to the buzzing chatter of many users, we’ve compiled a balanced view of what makes this printer shine-and where it might trip up the average DIY t-shirt enthusiast.

| Pros | Cons |

|---|---|

| Outstanding Print quality Vibrant, crisp, and detailed prints thanks to the innovative white ink mixing system. |

Setup Can Be Tricky Some users find the assembly and software installation complicated initially. |

| High-Speed Output The XP600 printhead doubles printing speed, perfect for boosting productivity. |

Software USB Key Required Operating the software needs a USB “dongle,” which can be easy to misplace. |

| Excellent Customer Support Responsive, helpful, and available even at odd hours to solve problems fast. |

Noise Levels Vary Printer runs quietly most of the time but can get loud when cleaning print heads. |

| Space-Saving Design Compact and lightweight with an integrated ink tank-ideal for desktop setups. |

Limited Print Width Best suited for hobbyists; small businesses might find the 8-inch width limiting. |

| Mess-Free Ink Filling Bottles and the white ink stirring system reduce clogging and ink waste. |

Occasional Hardware Issues A few reports of damaged components on arrival, though these didn’t always affect print quality. |

while the DTF Printer A3 impresses with its quality output, speed, and customer service, its learning curve and some hardware/software quirks require patience and a little troubleshooting. If you’re ready to invest some time upfront,this machine rewards you with professional-level prints and a reliable partner for your DIY t-shirt projects.

As we wrap up our honest take on the DTF Printer A3, it’s clear that this machine offers impressive print quality and vibrant, long-lasting results that easily stand out in the DIY T-shirt world. While the setup process might have its learning curve, the exceptional customer service and support truly make a difference in turning any initial hurdles into smooth sailing. Its high-speed printing and innovative white ink mixing system bring solid value for both hobbyists and creatives looking to elevate their printing game without breaking the bank.

Whether you’re starting fresh or looking to upgrade, this printer balances cutting-edge features with practical usability-making it a compelling choice if quality and speed matter most to you. We hope our review helps you make an informed decision on adding the DTF Printer A3 to your creative toolkit.Ready to see it in action for yourself? Check out the DTF Printer A3 and start bringing your designs to life today: Buy the DTF Printer A3 now on Amazon.

As an Amazon Associate I earn from qualifying purchases. Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates. All images belong to Amazon